T-flex TM 300 Series

T-Flex 300

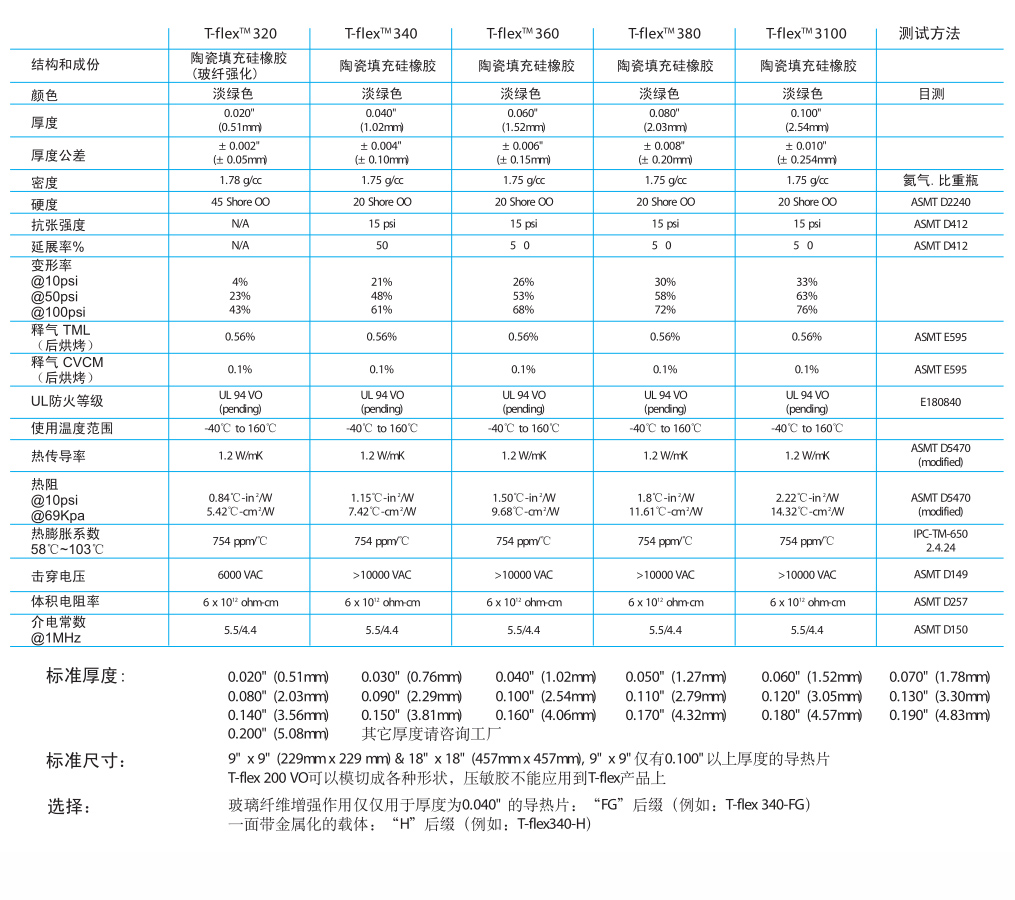

T-Flex 300 is a unique composite material blending silicone gel and ceramic powder, engineered to balance softness, conformability, thermal resistance, and cost-effectiveness for high-speed computing and telecommunications applications.

Under 50 psi pressure, T-Flex 300 achieves 50% compression of its initial thickness. This high compliance allows it to conform like a "carpet" over components, enhancing thermal transfer. The material exhibits low permanent set, enabling reuse over multiple assembly cycles.

T-Flex 300 combines exceptional flexibility with reliable thermal performance. With a thermal conductivity of 1.2 W/mK, it delivers low thermal resistance even under minimal compression forces.

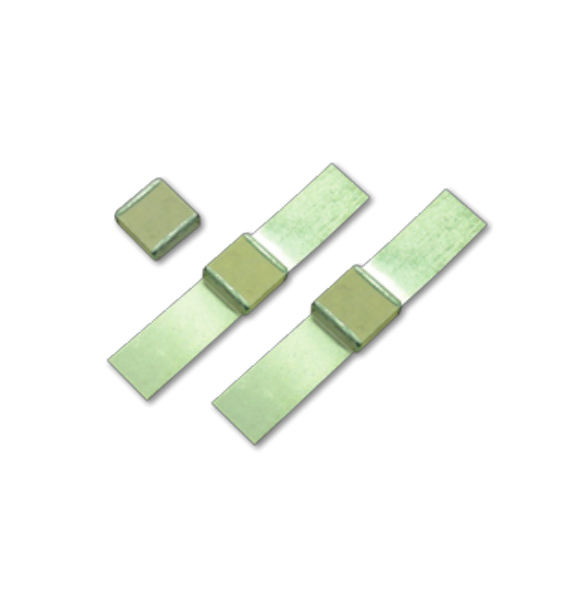

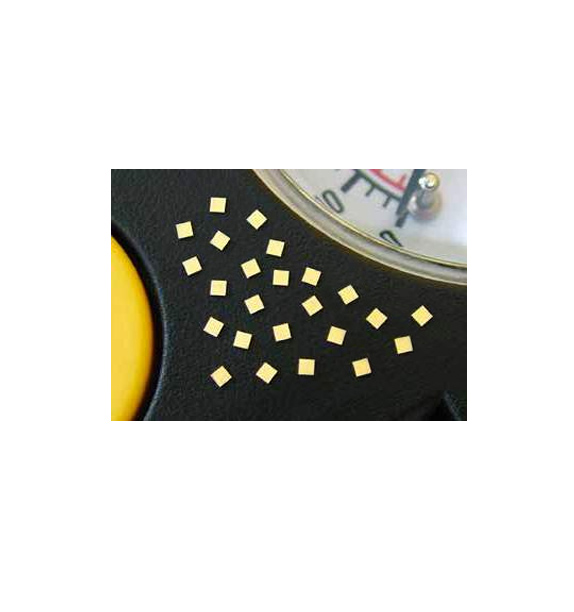

Metallized liners are available for easy placement, handling, and rework. Comparative testing shows T-Flex 300’s metallized liners outperform silicone-based alternatives in thermal performance. The low coefficient of friction of these liners also simplifies installation in sliding-fit assemblies, such as cards inserted into backplanes.

Key Features & Benefits:

- Outstanding Conformability: Adapts to irregular surfaces with minimal pressure.

- Thermal Conductivity: 1.2 W/mK for efficient heat dissipation.

- Reusable Design: Minimal permanent deformation ensures longevity.

- Thickness Range: 0.5 mm to 5 mm for versatile applications.

- Metallized Liner Option: Enhances thermal performance and ease of installation.

Applications:

- Laptops and Desktops: Cooling for CPUs, GPUs, and chipsets.

- Telecom Equipment: Base stations, routers, and RF modules.

- Hard Disk Drives (HDDs): Thermal management in data storage.

- DVD Players: Heat dissipation in consumer electronics.

- Flat-Panel Displays: Thermal regulation for LED/LCD screens.

- Memory Storage Modules: RDRAM and high-speed memory solutions.

- Power Conversion Systems: Inverters, converters, and motor drives.

Represented Brands:Laird